Make your own mailbox stove

Visitors to Boyslife.org were curious about how to build the mailbox stove that was depicted in the November 2007 issue of Boys’ Life (“Come And Get It!”).

You ask for it, you got it. We got the guys from Troop 33, Charlotte, N.C., to show us how you can make your own stove.

You ask for it, you got it. We got the guys from Troop 33, Charlotte, N.C., to show us how you can make your own stove.

Expect to spend at least half a day building (less if an adult uses power tools to speed some of the cutting) and between $60 and $80 on supplies (cut costs by recycling damaged metal mailboxes and by using nuts, bolts and washers already on hand).

The mailbox stoves lets Troop 33 bake, simmer and stay warm on windy days when campfires aren’t practical.

“It looks very complicated, but once you get started, one thing follows the next and it comes together pretty easily,” said Scout Rob Hagan, 15. “Once you get the hang of working with the tools and materials, you can make it pretty fast.”

MATERIALS:

- Jumbo steel mailbox ST20 series

- Elite steel mailbox regular size

- ½ grid galvanized wire screen (about 1-2 square feet)

- Three 36-inch-long all-thread metal rods (1/4 inch – 20 tpi)

- White marking tool, such as a white grease pencil or crayon

- Black permanent marker

- Four ¼-inch bolts approximately one inch long.

- ½-pound box of ¼-inch nuts

- ½-pound box of No. 8 deck screws 2-1/2 inch long

- ½-pound box of ¼-inch washers

- 1/8-inch aluminum strip 2 inches tall by 13 inches long (Note: This is for the temperature-control catch/handle. It can also be made of 1/16-inch steel by adults in a workshop.)

- .025-inch thick sheet metal 12 inches by 18 inches

- Wooden handle for temperature-control catch. Can be made from 1-inch diameter hardwood.

- Large metal clip, such as a spring clip, to hold door closed while cooking

- Cooking thermometer used for grills (must have locking nut to hold instrument in place)

- Furnace cement (black)

- Corner “L” bracket approximately 1-inch by 1-inch by ¾ inch wide

- Cabinet or drawer handle (not plastic)

- 9×9-inch metal grate to sit atop the smaller box opening when cooking.

TOOLS:

- Power drill

- 5/16-inch heavy-duty drill bit

- 1/8-inch heavy-duty drill bit

- 2-1/2-inch wood/metal hole saw

- Jigsaw with metal-cutting blade

- Power screwdriver

- Vice to hold rods while cutting

- Putty knife

- Flat metal file

- Tape measure

- Hacksaw

- Ruler

- Hammer

- Center punch

- Two 7/16-inch open wrenches

- Pliers

- Tin snips

- Safety glasses

DIRECTIONS:

Step 1. On bottom of smaller box, measure and mark (using white grease pencil) 16 inches away from side that opens. Center equal distance from edges. This will become the air intake hole.

Step 1. On bottom of smaller box, measure and mark (using white grease pencil) 16 inches away from side that opens. Center equal distance from edges. This will become the air intake hole.

Step 2. On side of box, measure and mark a parallel line 14 inches from open end. Mark line at two inches, four inches and six inches from bottom. Repeat on other side of box.

Step 2. On side of box, measure and mark a parallel line 14 inches from open end. Mark line at two inches, four inches and six inches from bottom. Repeat on other side of box.

Step 3. Using center punch and hammer, tap each mark to create a small dent (to keep drill bit from slipping). Drill holes using 5/16-inch bit.

Step 3. Using center punch and hammer, tap each mark to create a small dent (to keep drill bit from slipping). Drill holes using 5/16-inch bit.

Step 4. On right side of front door (flag side), center corner brace on door three inches from bottom and flush to right side. Mark then drill with 5/16-inch bit.

Step 4. On right side of front door (flag side), center corner brace on door three inches from bottom and flush to right side. Mark then drill with 5/16-inch bit.

Step 5. Use hole bit to cut air-intake hole in back of mailbox (where previously marked). Empty shavings from box.

Step 5. Use hole bit to cut air-intake hole in back of mailbox (where previously marked). Empty shavings from box.

Step 6. Cut steel rods using hacksaw to 6-5/8 inches long (cut three) and 11-1/2 inches long (cut six). File smooth with hand file. Each rod will take four nuts.

Step 6. Cut steel rods using hacksaw to 6-5/8 inches long (cut three) and 11-1/2 inches long (cut six). File smooth with hand file. Each rod will take four nuts.

Step 7. Insert three smaller bolts through holes in sides of small box and secure with nuts. Note: Rods with nuts should not extend out past ¼ inch on each side.

Step 7. Insert three smaller bolts through holes in sides of small box and secure with nuts. Note: Rods with nuts should not extend out past ¼ inch on each side.

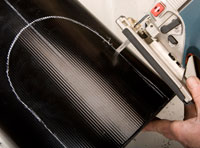

Step 8. Laying ½-inch galvanized screen atop mouth of small mailbox, trace shape using permanent marker. Cut two shapes using tin snips. Push into box to rest upon rods.

Step 8. Laying ½-inch galvanized screen atop mouth of small mailbox, trace shape using permanent marker. Cut two shapes using tin snips. Push into box to rest upon rods.

Step 9. Against bottom edge of large box, draw perpendicular lines at 2 inches, 7 inches and 13 inches from opening side. Then mark at 3 inches and 7 inches up line from bottom. Tap with hammer and center punch to dent slightly, then drill with 5/16 bit.

Step 9. Against bottom edge of large box, draw perpendicular lines at 2 inches, 7 inches and 13 inches from opening side. Then mark at 3 inches and 7 inches up line from bottom. Tap with hammer and center punch to dent slightly, then drill with 5/16 bit.

Step 10. Measure location of air-intake hole on the bottom of the small mailbox and apply same distance to back end of large box. Use hole drill to cut.

Step 10. Measure location of air-intake hole on the bottom of the small mailbox and apply same distance to back end of large box. Use hole drill to cut.

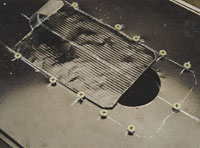

Step 11. Mark centerline on top of both boxes. Using these lines as guides, set smaller box atop larger box and trace outline of shape. Have adult partner drill a pilot hole with 5/16 bit, then cut box using jigsaw. Save leftover piece.

Step 11. Mark centerline on top of both boxes. Using these lines as guides, set smaller box atop larger box and trace outline of shape. Have adult partner drill a pilot hole with 5/16 bit, then cut box using jigsaw. Save leftover piece.

Step 12. Using pliers, open hole slightly (as necessary) to insert smaller box into larger box. The air intake holes should line up.

Step 12. Using pliers, open hole slightly (as necessary) to insert smaller box into larger box. The air intake holes should line up.

Step 13. Once fitted together, use the 1/8 drill bit to drill six holes randomly in the bottom of the large box and into the smaller box. Screw a deck screw into each hole in order to secure the two boxes together.

Step 13. Once fitted together, use the 1/8 drill bit to drill six holes randomly in the bottom of the large box and into the smaller box. Screw a deck screw into each hole in order to secure the two boxes together.

Step 14. Trace a 4-inch-by-6-inch square in the center of the scrap piece cut from the large box. Include a one-inch-wide tongue at the top. This will become the handle used to slide the air-intake door open and closed. Hammer flat. Cut with tin snips or jig saw (adult). Dress with file to smooth edges. Save leftover pieces.

Step 14. Trace a 4-inch-by-6-inch square in the center of the scrap piece cut from the large box. Include a one-inch-wide tongue at the top. This will become the handle used to slide the air-intake door open and closed. Hammer flat. Cut with tin snips or jig saw (adult). Dress with file to smooth edges. Save leftover pieces.

Step 15. Trace an outline of the door around the air-intake hole. Mark area for deck screws to be placed to hold door in place along door’s edges. Drill holes with 1/8 drill through both boxes, then install deck screws. Fit door in place.

Step 15. Trace an outline of the door around the air-intake hole. Mark area for deck screws to be placed to hold door in place along door’s edges. Drill holes with 1/8 drill through both boxes, then install deck screws. Fit door in place.

Step 16. Using one of the leftover pieces trimmed from the air-intake door, measure the width of the gap space between the bottom of the small box and the rear of the large box. Trim with tin snips, adjust as necessary with pliers and insert gently into space. Piece should hold itself into place.

Step 16. Using one of the leftover pieces trimmed from the air-intake door, measure the width of the gap space between the bottom of the small box and the rear of the large box. Trim with tin snips, adjust as necessary with pliers and insert gently into space. Piece should hold itself into place.

Step 17. Bend sheet metal horizontally to replicate the curve of the smaller box. Insert into larger box, along front edge of smaller box. Sheet becomes a shield to evenly distribute the heat inside of the oven.

Step 17. Bend sheet metal horizontally to replicate the curve of the smaller box. Insert into larger box, along front edge of smaller box. Sheet becomes a shield to evenly distribute the heat inside of the oven.

Step 18. Insert the six 11-1/2-inch rods into the holes in the side of the large box, securing each rod with four nuts (two nuts on each rod on the inside of box, two nuts on rod on outside of box).

Step 18. Insert the six 11-1/2-inch rods into the holes in the side of the large box, securing each rod with four nuts (two nuts on each rod on the inside of box, two nuts on rod on outside of box).

Step 19. Trace pattern onto aluminum strip. Drill pilot holes in each of the curved areas using 5/16 bit. Use hacksaw to remove pieces to form teeth. Bend handle forward at 90-degree angle, with teeth on the right.

Step 19. Trace pattern onto aluminum strip. Drill pilot holes in each of the curved areas using 5/16 bit. Use hacksaw to remove pieces to form teeth. Bend handle forward at 90-degree angle, with teeth on the right.

Step 20. Through flag hole on the right side of small box, create a catch for the lid arm. Leaving about a quarter-inch of space on the shaft of the bolt, secure it using a washer and nut on the outside of the box and another washer and nut on the inside of the box.

Step 21. Attach corner bracket to right hand side of door on smaller box using the hole drilled in step 4. Attach in this order: Bolt, washer, corner brace, mailbox, washer, locking washer, and nut.

Step 21. Attach corner bracket to right hand side of door on smaller box using the hole drilled in step 4. Attach in this order: Bolt, washer, corner brace, mailbox, washer, locking washer, and nut.

Step 22. Attach aluminum arm to the corner brace in this order: Bolt, washer, aluminum arm, washer, corner brace, washer, nut, jam nut. The jam nut helps keep the other nut from working loose. Note: Secure arm in place loosely, so it can easily move up and down.

Step 22. Attach aluminum arm to the corner brace in this order: Bolt, washer, aluminum arm, washer, corner brace, washer, nut, jam nut. The jam nut helps keep the other nut from working loose. Note: Secure arm in place loosely, so it can easily move up and down.

Step 23. Attach clip to top front of large mailbox. Drill a hole for bolt, if necessary. Adjust clip and attachment to allow clip to hold door shut securely. Note: Clips with flatter profiles are easier to work with than the spring clip shown in photo.

Step 23. Attach clip to top front of large mailbox. Drill a hole for bolt, if necessary. Adjust clip and attachment to allow clip to hold door shut securely. Note: Clips with flatter profiles are easier to work with than the spring clip shown in photo.

Step 24. Mark and drill holes to secure drawer handle to front of door on large box. Insert grill thermometer at top of door (drilling hole, if necessary) and secure in place with nut.

Step 24. Mark and drill holes to secure drawer handle to front of door on large box. Insert grill thermometer at top of door (drilling hole, if necessary) and secure in place with nut.

Step 25. Seal joints, holes and gaps using a generous amount of furnace putty. This seals the heat into the oven and binds the two boxes together so the heat can’t escape. Allow to harden overnight before using the oven.

Step 25. Seal joints, holes and gaps using a generous amount of furnace putty. This seals the heat into the oven and binds the two boxes together so the heat can’t escape. Allow to harden overnight before using the oven.

TO OPERATE:

Fuel oven through “chimney,” or the smaller box sticking upright. Fuel through the mouth of the smaller box onto the screens sitting inside.

Start with paper and small wood shavings to help the fire catch. Slowly add larger and larger shavings and splinters to help the fire grow. When ready, fuel with small blocks of wood. Soft woods, like pine, help the fire burn quickly. Hardwoods, like oak, create nice coals that create consistent heat. You can also burn pinecones and other yard debris.

“Just slide this door up and down to let in more air to help the flames burn, or to lower the air intake to take down the fire a little,” says 15-year-old Scout Rob Hagan.

Control the oven temperature by opening and closing the door of the small box. Closing the door increases the oven heat and vice versa. With practice, you’ll be able to control the temperature while you cook.

Use a small cookie sheet to bake inside the oven. Set a skillet or pot atop the 9×9 grate set atop the mouth of the smaller box.

Enjoy your meal!

Nice

Cool

Awesome

Shocking

Just curious,do you sell these.

I would question the use of galvanized metal for cooking, this could lead to Zinc poisoning. Also, there could possibly be some dangers from the furnace putty as well. Just my two cents.

Yes! It works great!. We have been using it for years to make everything from dinners to desserts to popcorn! Thanks for sharing the article!

Why not just use a reflection oven? Cheaper, lighter, easier to make. Seems more scout friendly and feasible.

An outline drawing of the finished project and maybe photos from the side, front and back and I could visualize the stove as a whole. thanks for submitting the article.

yeah i’ve seen stuff like that… for those of you who built it that does it work?

I pictured a big old metal mailbox with coals and a shelf – whew…it looks complicated for this Scout!