How to Make a Fast Pinewood Derby Car

Packs nationwide are gearing up for their annual Pinewood Derby. There are a variety of ways to make your Pinewood Derby car go faster. Explore the following tips to optimize your car’s performance and gain a competitive edge in an upcoming race.

BASIC GUIDELINES FOR PINEWOOD DERBY CAR DESIGN

The possibilities are endless when it comes to picking a shape for your Pinewood Derby car. Before you begin, consider the following general guidelines:

Avoid Pointed Noses: A pointed nose will make it difficult for your Pinewood Derby car to rest on the pin at the starting gate. It may also cause your Pinewood Derby car to get bumped around when the pin drops, and it can create problems for electronic timing systems at the finish line.

Weight Distribution: Leave ample wood in the rear of the Pinewood Derby car so you can place additional weight there. Concentrate the majority of the weight in the rear for optimal performance.

Maximum Weight: Aim for the maximum allowable weight, typically limited to 5 ounces in most races. If your car falls short of this weight, strategically add coins or other weights to meet the requirement.

Clarity in Orientation: Clearly distinguish the front and back of your Pinewood Derby car. In many races, the race officials — not you — will actually place each Pinewood Derby car on the track. Sometimes the officials put the Pinewood Derby car on the track backward because they can’t tell which end is which.

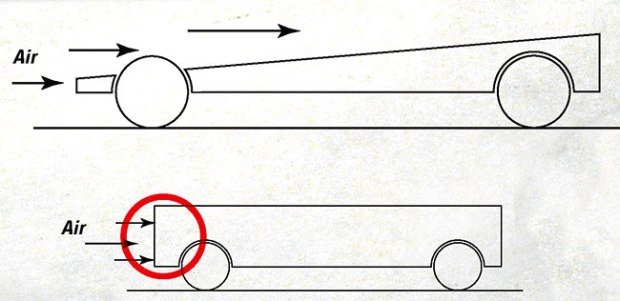

Aerodynamic Design: Select a design that facilitates smooth airflow over and around the Pinewood Derby car body. Pinewood Derby cars with aerodynamic profiles go faster.

See photo galleries of hundreds of Pinewood Derby car designs.

10 STEPS FOR DESIGNING AND BUILDING YOUR PINEWOOD DERBY CAR

You don’t have to strive for the fastest Pinewood Derby car to have fun competing in your Pinewood Derby. But if you and a helpful adult are willing to put in the extra time and effort, these tips are for you.

1. Bake the Block: Start your Pinewood Derby car project by baking the wood block at 250 degrees for two hours. This removes moisture and lightens the block, allowing you to place more weight at the rear of the car where you actually want it.

2. Crafting the Design: Outline your Pinewood Derby car on paper, cut it out, and affix it to the wood block.

Remember, a rectangular car is not an aerodynamic design. The most basic aerodynamic design is a simple wedge. If you don’t have time to design a complex car, a wedge will work just fine.

Download a Pinewood Derby car template PDF to help you create your design.

3. Rough Cut the Design: Use a coping saw or enlist the help of a responsible adult with a power tool to cut out the rough shape of your Pinewood Derby car.

4. Shape Your Car: Smooth edges and shape your car using sandpaper. An adult can assist with a rotary tool or other shaping tools.

5. Sand and Paint Creatively: Reduce friction by smoothing the car’s surface and paint an awesome design to make it look great.

How to paint your Pinewood Derby car to give it a shiny finish.

6. Axles and Wheels Alignment: Make sure they are aligned perfectly straight. You can test the alignment of your axles by pushing your car across a smooth floor or table. It should roll smoothly in a straight line.

— Consider a Three-Wheeler: Raise one wheel about 1/16 inch higher so it never actually touches the track. Less friction = more speed. Rules vary from pack to pack, so make sure to check your pack’s Pinewood Derby rules to make sure three wheelers are allowed in your race.

— Extend the Wheelbase: Maximize the distance between front and rear wheels. Again, make sure this is allowed in your race.

Learn about polishing Pinewood Derby axles and wheels to reduce friction.

7. Secure Axles with Glue: Glue the axles firmly in their holes to ensure that they stay perfectly placed, but make sure you don’t get glue on your wheels.

8. Strategic Weight Addition: Remember to make your Pinewood Derby car as heavy as the rules allow. In general, it’s best to place weight to the rear of your car because a heavier rear increases speed.

Learn scientific Pinewood Derby speed tips from a former NASA engineer.

9. Use Graphite: Add graphite or another dry lubricant to reduce friction. The less friction between the body and wheel, the better.

10. Have fun! And finally, remember the most important rule of a Pinewood Derby is that it’s supposed to be fun. While you should always strive to do your best, don’t get caught up in winning or having the fastest car. Just enjoy the ride.

Adapted from the book “Pinewood Derby Speed Secrets,” DK Publishing, $12.95 softcover.

Wrong about the 3 wheels being less friction. I’m surprised that got published, it’s a myth. The friction is just transferred to the other wheels. But you do get more rotational energy and thus a faster car.

Wrong, less contact equals less friction so it does get reduced. Weight distribution gets spread out but not friction.

Sorry, but I think speedthree has it right. Friction is a function of the coefficient of friction, and the normal force between the surfaces. The surface area does not factor. However, the wheels have a rotational inertia that needs to be overcome, so having one less wheel to force to rotate will result in increaded acceleration.

The “Avoid designs with a pointed nose” guideline directly contradicts a different BSA publication. That tells you to make a narrow area in the center of the car (nearly pointed) so that the race starter has to “work” to get the car placed in the center of the track, so that the wheels are touching the sides of the track.

I saw one car with a notch in the front where the starting pin rested. The result was the body of the car being a bit ahead of all the others. It wasn’t against the pack’s rules, and the car didn’t win anyway…but it was sort of clever.

what happens if i bake it after cutting it?

baking it will reduce your un-weighted mass so you can better place weight where you want it. doing so after cutting risks warping the car body. bake before cutting, especially with thin or flat shapes.

Those must have been made by the pros

which wheel should I lift, the front or the rear?

rear wheels

One thought- since its better to raise a rear wheel on a 3 wheeler, how does that theory work with the other “go-to” of placing weight at the rear? I would think there would be tendency for the opposite front wheel to pull up off the track.

Usually a front wheel, since you’re placing the weight in the back, it could wobble back and forth if you lift a rear wheel.

Always raise one of the front wheels

Raise a front wheel and use dry graphite. I would smoke everyone, every year. Also, take fine grit sand paper and the inside of the nail head, there are usually small burs and imperfections that add friction.

Raising a back wheel would be disastrous. You only want one wheel fighting for direction, as it will limit the time the inside track bangs the wheels. Lifting a rear wheel wouldn’t solve it the same way.

nice

It would be nice if there was a official rule book and measuring box.

awesome!!! trying it out now

In certain races, there are.

Great info… but a good piece of pine wood, round wheels, and straight axles never hurt either… have fun

yeah in my pack you have to use the given wheels

Your pack committee should establish an adult race. This lets the dads satisfy their personal competitive urges and lets the boys be boys. I always won with a simple wedge and the three wheel trick.

yea, i usually make a wedge, always three-wheeled and axles sanded with at least 6-8 different sandpapers, each a different roughness. what really helps is cutting the sides off about 1/8 inch everywhere except where the wheel and axle are. this prevents the wheel from ever rubbing against the car, significantly reducing friction.

In my pack, we’re doing that this year.